Identifying and solving quality problems, preventing defects, and improving customer satisfaction.

Analyzing processes to maximize the quality of the process itself and the products being produced.

Use Problem Solving methodologies to:

- Improve Quality (Prevent Defects)

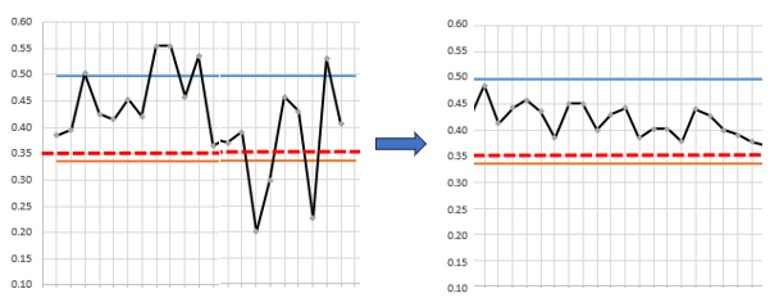

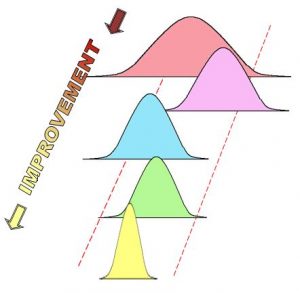

- Reduce Variation

- Standardize

Quality Planning

Quality Planning

- Define Inputs and Requirements of:

- Customer

- Product

- Process

- Regulatory

- Impact Analysis

- Reviews to verify input requirements are addressed in design

Process Monitoring, Analysis & Improvement

- DMAIC and PDCA Methodologies and Problem Solving Tools

- Process Mapping

- Descriptive Statistics:

- Data Types: Continuous (Variable) or Attribute (Descriptive) data

- Central Tendency: Mode, Median, Mean

- Dispersion: Variance, Standard Deviation, Range

- Data or Process Performance visualization:

- Pareto

- Histogram

- Charts (Run chart, Bar, Pie)

- Box & Whisker

- Scatter plots

- Statistical Process Control (SPC)

- Process Capability Studies

- Cost of Quality / Cost of Poor Quality

- Prevention costs

- Appraisal costs

- Internal Failures

- External Failures

- Measurement System Analysis (Gage R & R Studies)

- Analysis

- Data Stratification

- FMEA

- Cause & Effect

- 5Why’s

- FTA

- ANOVA

- Inferential Statistics

- Improvement: Develop Countermeasures, Kaizen, DOE, Poka-Yoke

- Standardize, Process Monitoring (SPC and process audits), Control Plans and Continuous Improvement